Cylinder Heads are pressure checked.

Valve Seats are renewed via three-angle precision cutting and resurfacing.

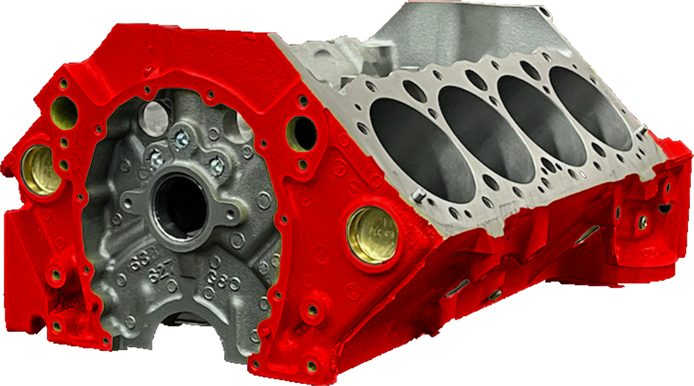

Cylinder walls are then bored with deck plates, then diamond-honed to perfection. Oil and water galleys (passageways) are subjected to pressure cleaning.

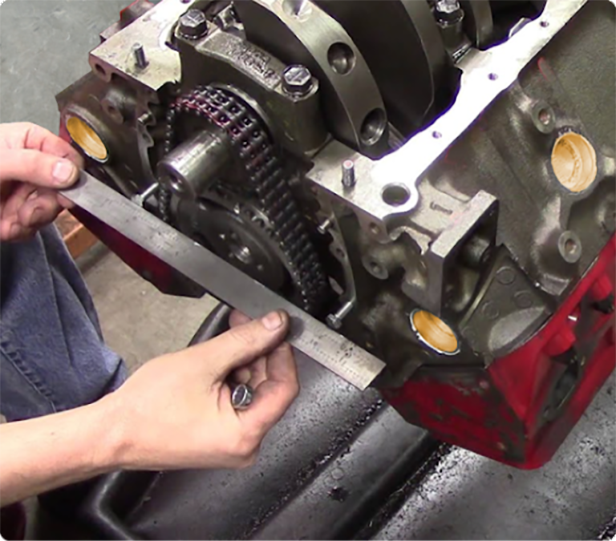

Crankshafts are ground & polished to .002 clearance.

Camshafts are ground to OEM specifications, hardened & polished. That, or we install new, OEM-spec from our established & trusted suppliers (application-dependent).

Engines are run on the Sim test machines with preheated, pressurized oil where compression, timing, galley functionality is verified and documented.

Engines are now wrapped and secured to a pallet, boxed and ready for shipment. Internationally shipped engines and engines that will be stored for extended periods are pretreated with corrosion prevention spray.